The Practical Choice for Industrial Applications

Among all types of charcoal, Mixed-wood Charcoal stands out as the most economical and versatile fuel choice for large-scale applications. Produced from a carefully balanced blend of hardwood and softwood materials, it offers a steady heat output suitable for a wide range of industrial uses — from food processing and drying to heating and manufacturing.

While premium charcoal types like Binchotan, Hardwood or Sawdust briquettes are often chosen for culinary or luxury applications, it plays a different yet equally important role: it powers industries. Its strength lies in affordability, stability, and abundance, making it the go-to option for businesses that value both performance and cost efficiency.

What Is Mixed-Wood Charcoal?

It is produced by carbonizing various wood types together under controlled temperature and oxygen conditions. By blending different woods, producers can achieve a balanced charcoal that lights easily, burns consistently, and remains affordable to produce at scale.

Each batch undergoes carbonization in traditional brick kilns or modern steel kilns, followed by cooling and sorting to ensure uniformity in size and quality. Although it may not reach the ultra-high density or long burn time of pure hardwood charcoal, it provides excellent heat for continuous processes and is reliable for factories that operate round the clock.

1. Cost-Effective for Large-Scale Use

When industries run large operations, fuel cost becomes one of the biggest factors affecting profit margins. It provides a budget-friendly solution that doesn’t compromise on reliability. Manufacturers can therefore keep production costs low while still meeting high-volume demand.

For factories that use several tons of charcoal each month, switching to Mixed-wood Charcoal can reduce operational costs by up to 30%, compared to using only premium-grade charcoal. It’s a sustainable choice that balances economics with practicality, ensuring that businesses remain competitive without sacrificing fuel performance.

2. Reliable Heat & Consistent Performance

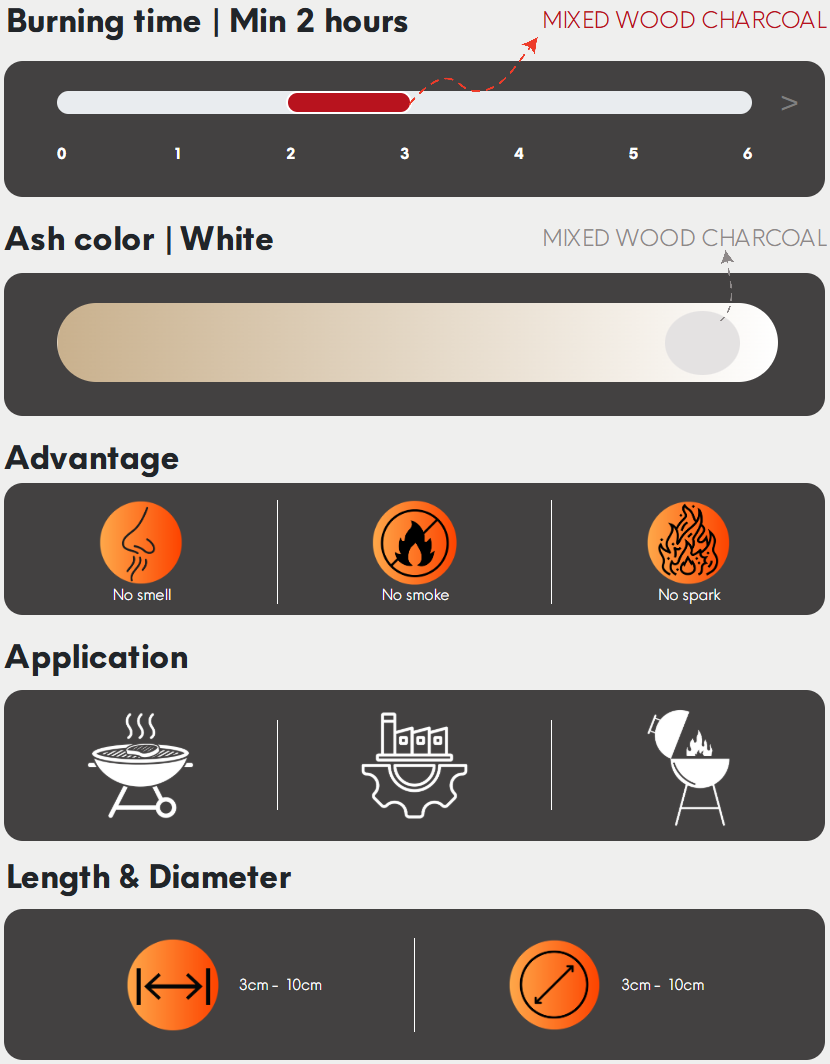

Despite being a blend, Mixed-wood Charcoal burns steadily and predictably. The combination of hardwood and softwood ensures that ignition is quick yet heat output remains stable once fully lit. This consistent heat allows industrial users to maintain control over temperature-dependent processes — such as drying or roasting — without frequent refueling or interruptions.

Additionally, modern carbonization methods used by manufacturers like Vinachaki help reduce impurities and moisture content, improving energy efficiency and minimizing smoke. This not only enhances working conditions but also reduces the environmental impact of industrial fuel use.

Industrial Applications

Industrial Applications

3. Sustainability & Practical Benefits

Another advantage of Mixed-wood Charcoal lies in its environmental sustainability. By utilizing leftover wood and byproducts from the timber industry, it reduces waste and promotes a circular use of natural resources. The production process generates fewer carbon emissions compared to fossil fuels, making it a greener option for factories looking to lower their environmental footprint.

Moreover, Mixed-wood Charcoal burns cleaner than many other low-cost fuel types, producing less smoke and odor while still providing effective heat. Its light weight and easy handling also make storage and transportation more convenient, further reducing operational costs.

For companies seeking a practical, efficient, and eco-conscious energy source, Mixed-wood Charcoal stands out as the perfect balance between performance and sustainability. It’s an industrial fuel that proves you don’t have to sacrifice quality for cost-efficiency.

4. Ideal for Industrial-Scale Applications

Mixed-wood Charcoal is not just about affordability — it’s about functionality and adaptability. It works well in kilns, boilers, dryers, and furnaces across various industries that need constant and reliable heat.

Because it’s lighter than pure hardwood charcoal, transportation and handling are easier, especially when dealing with bulk quantities. Businesses benefit from lower logistics costs, simplified storage, and faster loading or unloading times — all of which contribute to improved efficiency.

For industrial users, it’s not just fuel — it’s a dependable energy solution that supports productivity while keeping expenses under control.